Process Engineering

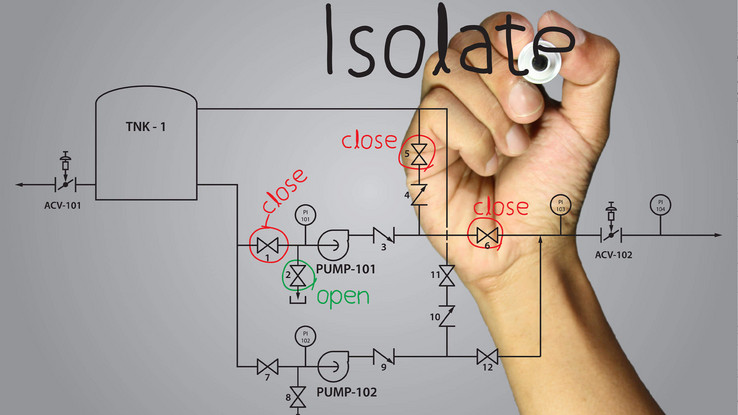

Engineering Solutions for Creating PF and P&I Diagrams

Process engineering deals with the production and conversion of a wide array of materials, including solids, liquids and even gases. The application fields can vary widely, for example they include grain processing, paper production, metal extraction from ores and much more. EPLAN engineering design software creates process flow diagrams (PFDs), piping and instrumentation diagrams (P&IDs), and optimizes and integrates your engineering processes regardless of the materials you manufacture or process.

CAE Software -Necessary Foundation for Efficient Engineering Processes

What applies to all engineering disciplines also applies to process engineering: By creating a basis for your engineering through compliance with regulations and standards and high-quality device data, you create the necessary foundation for efficient processes and workflows.

High-Quality Device Data for Your Projects

Using the EPLAN Data Portal provides you access to high-quality device and component data from a continually growing pool of manufacturers. This way you get all the necessary device data for process engineering from one source and can easily integrate it into your projects via drag-and-drop.

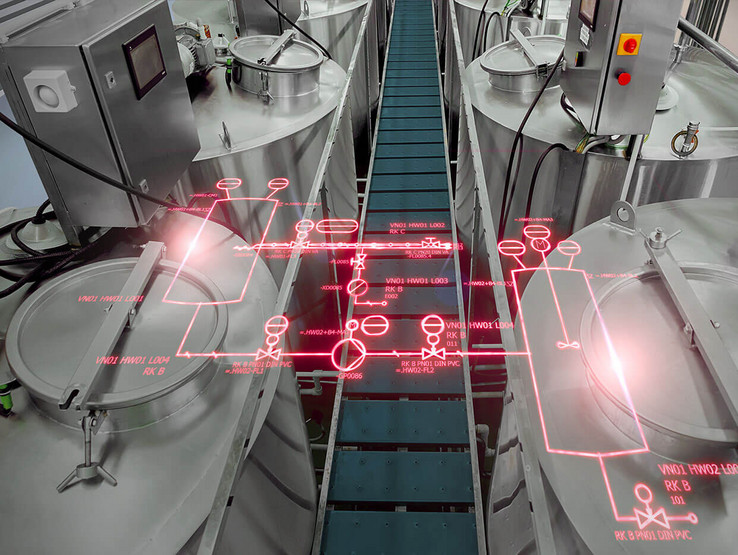

Focus on Interdisciplinary Design

Process engineering data is the central source of information for mechanical and plant engineering and its seamless transfer to fluid and electrical engineering is essential. This makes it important to optimize your processes on the basis of integrated engineering data. EPLAN solutions support you in this.

We're happy to help!

Would you like to find out more about our solutions or services? Then contact us – we’re here for you!